Mesh belt type spiral quick freezing conveyer

Model No.︰-

Brand Name︰Vinot network chain

Country of Origin︰China

Unit Price︰CNY ¥ 1466 / pc

Minimum Order︰1 pc

Product Description

Spiral freezer is a compact structure, wide application, covers an area of small, freezing capacity of energy-saving type quick freezing equipment is currently food processing enterprises at home and abroad for the frozen meat frozen product thickness, large volume, into the high temperature of the material of choice models.

Applicable scope: food, ice cream, pasta, meat, aquatic products, segmentation of fried foods, small food packaging etc..

brief introduction

Spiral freezer is a compact structure, wide application, covers an area of small, freezing capacity of energy-saving type quick freezing equipment is currently food processing enterprises at home and abroad for the frozen meat frozen product thickness, large volume, into the high temperature of the material of choice models.

Applicable scope: food, ice cream, pasta, meat, aquatic products, segmentation of fried foods, small food packaging etc..

Structure composition

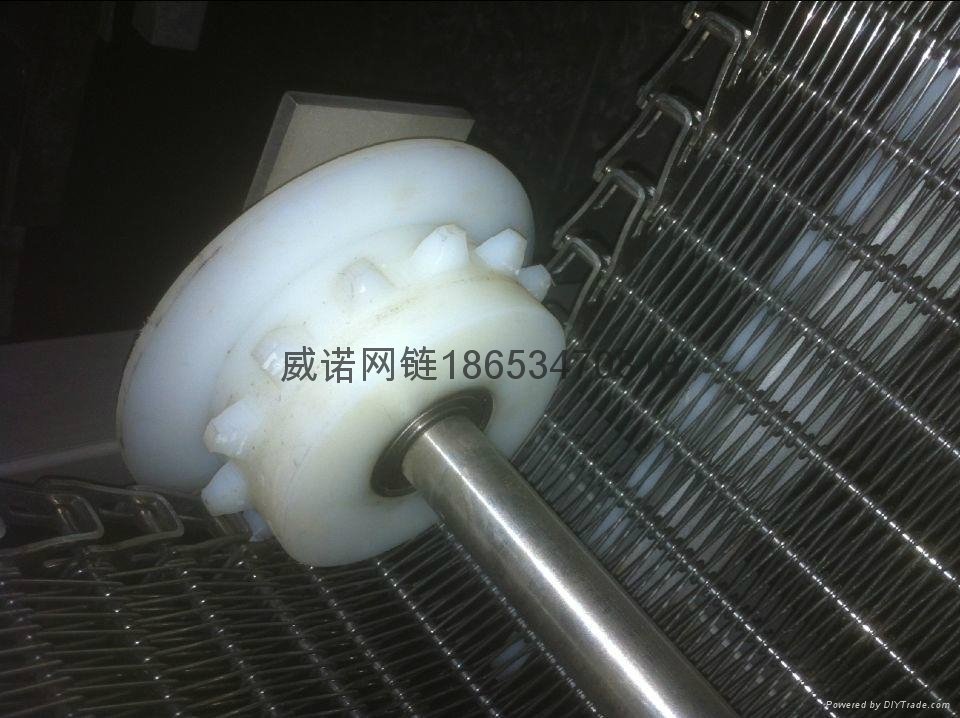

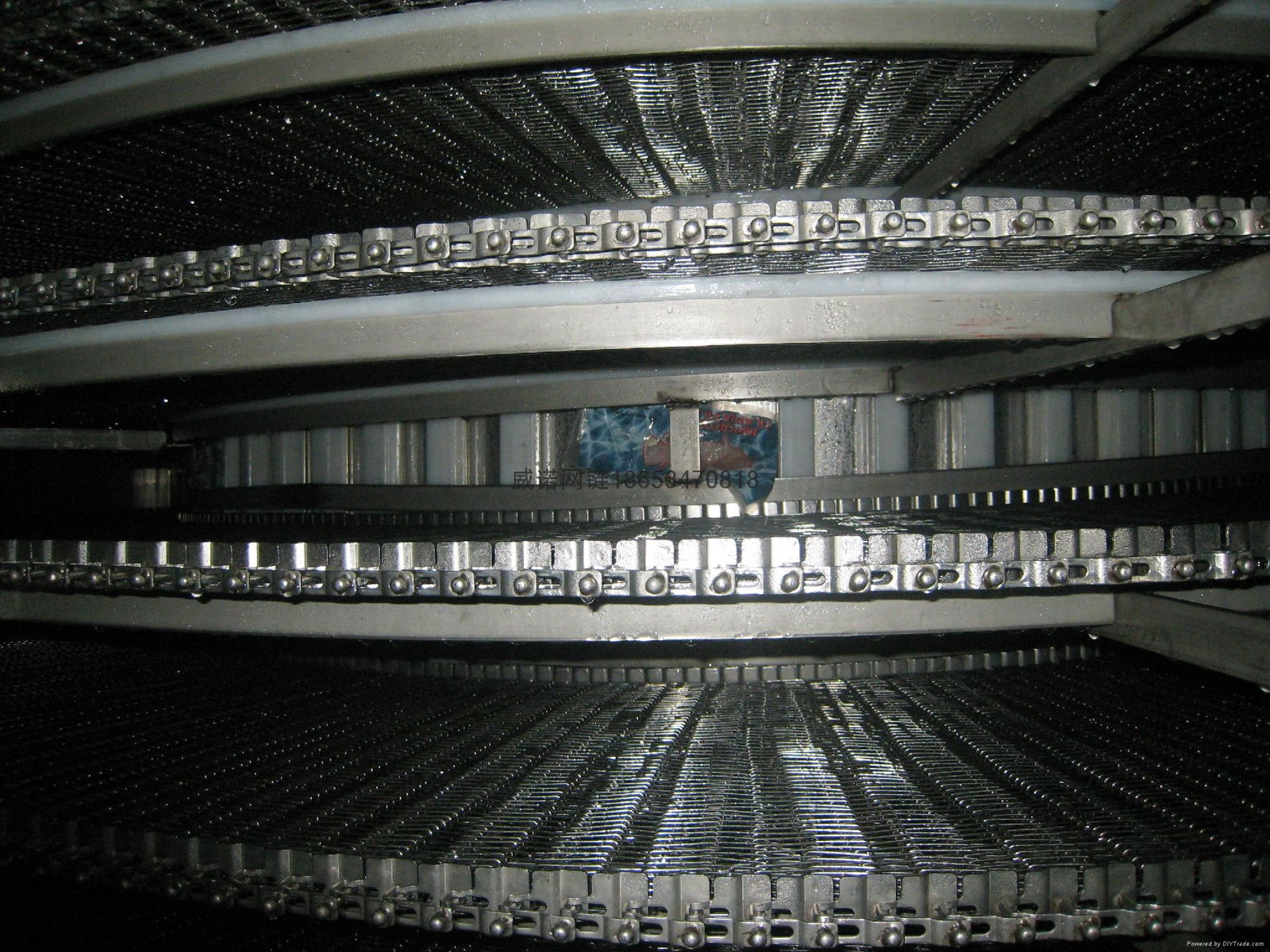

The spiral quick freezing machine is mainly composed of a transmission part, an evaporator, a base plate and an electric device.

The transmission part is composed of a transmission motor, a mesh belt, a rotary tower and an independent frequency converter;

Evaporator on the grounds stainless steel and aluminum fins, with variable fin pitch arrangement, ensure air circulation smooth, row evaporation tube can be for aluminium and copper pipes;

The base plate is made of stainless steel;

The electrical system consists of a stainless steel electric box and an intelligent control device;

characteristic

1 freezing capacity, due to the use of double drum structure, greater play to the spiral quick freezing machine;

2 compact structure, small floor area;

3 a large number of mechanical machining parts, eliminating the welding parts produced by welding deformation, welding stress concentration caused by transmission cumulative deviation, transmission of inconsistency;

4 transmission network with strong resistance to elongation, high wear resistance, so as to improve the service life and stability of the equipment;

5 equipment with a network with the operation of the device, at any time to monitor the operation of the network with the situation, to eliminate the network with poor operation, unnecessary losses.

Product Image